Safe Li-ion battery manufacturing vouching for smooth EV transition in India

The

transition to electric vehicles is gaining a lot of traction in recent years.

The rate at which it is being adopted across the globe for its cleantech

solutions, EVs are very likely to increase their overall share in the

automobile industry in the future. In addition to this, the advantage of low

maintenance cost is further strengthening the proposition of EVs in the market.

Even India is quite enthusiastic about the EV transition where the country

aspires to become the EV-first nation by 2030.

EVs are highly preferred for their eco-friendly solutions that omit the emission of harmful gasses into the air. Owing to this ability to check the vehicular exhaust, it is emerging as the best alternative to fossil-fuel vehicles. Here, the ability to run on electricity is the major game changer as it allows the vehicle to offer green solutions. This dependency on electricity underscores the importance of Lithium-ion batteries for powering the EV industry. Li-ion batteries are at the heart of the EV ecosystem and are highly preferred for their ability to generate high energy per unit mass in comparison to other electrical energy storage alternatives available in the market.

The Li-ion batteries exercise an edge over the others because of the advanced technology that allows for high energy efficiency, high power-to-weight ratio, good high-temperature performance, and low self-discharge. In addition to all the benefits, the batteries portray better energy storage density that can be accommodated in a small size.

The list of advantages goes endless with the ability to charge and discharge energy safely along with the capacity to charge in minimum time. As a result, Li-ion batteries are being sought globally for their highly competitive technology that is crucial for driving the unrivaled performance of EVs in the automobile segment. Playing such a significant role in powering the entire vehicle, Li-ion batteries make up 40-50% of the entire vehicle cost. And any fault in the battery can lead to calling off the EV from the market which can impede the growth of the entire industry. Hence, the transition towards EV mobility in India is impossible without the safe manufacturing of Li-ion batteries.

There

is a lot of concern about EVs catching fire which places a lot of

responsibility on the manufacturers to come up with highly competitive and safe

batteries. For which, highly controlled environmental conditions are required

for battery manufacturing. Considering that various components in Li-ion

batteries are highly hygroscopic in nature, it becomes imperative to regulate

and monitor the humidity level throughout battery manufacturing and assembling.

The entire process requires humidity to be maintained at less than 1% in a

stable environment.

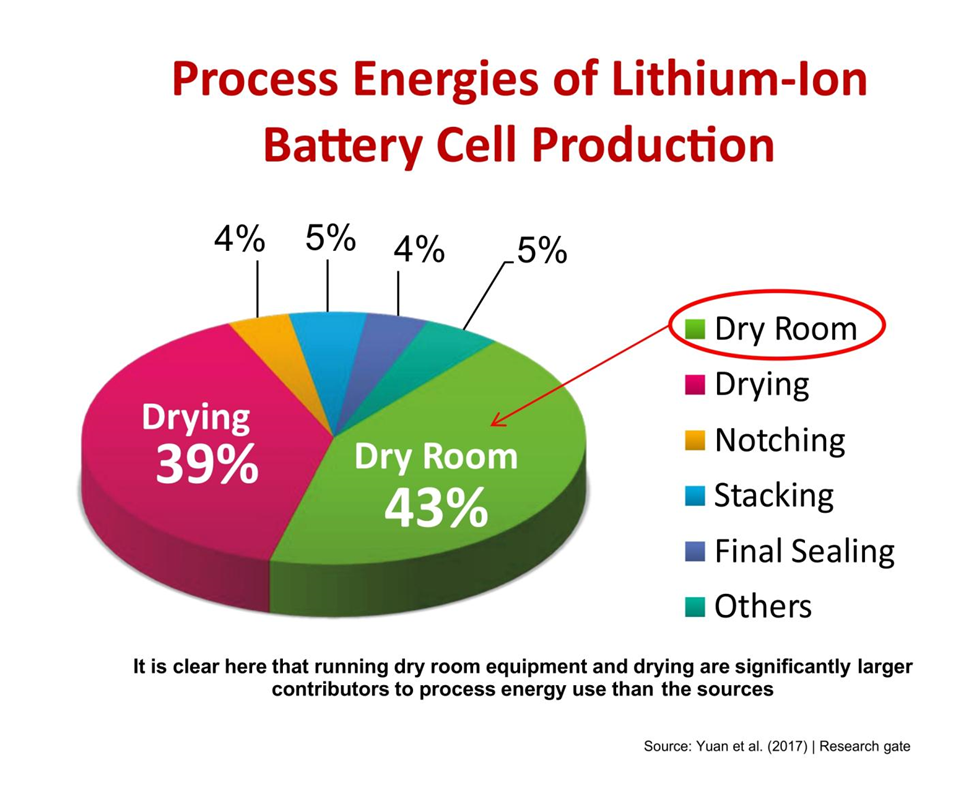

In order to achieve stringent environmental conditions, installing Dry Rooms in the battery manufacturing setup can suffice the purpose. Dry Rooms are well equipped with an Environment Control Dehumidification System that maintains the RH at less than 1% during lithium cell manufacturing and less than 10% during battery assembling. It is well adept at achieving extremely low dew points, reaching as low as -80°C with the help of moisture control equipment to render ideal processing of hygroscopic and moisture-sensitive materials.

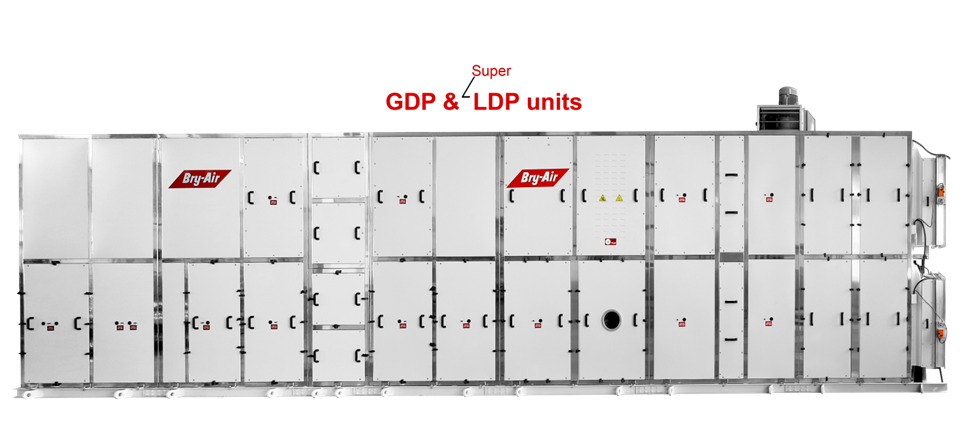

Gauging

the importance of desiccant dehumidification technology in Li-ion battery

manufacturing, Bry-Air Dry Rooms offer patented Environment Control Dehumidification System, Green DryPurge (GDP) series for providing dehumidification/ moisture control solutions

in perfect confluence with a refrigeration system to maintain the desired RH

within the narrow humidity bracket. It is further acing the entire battery

manufacturing process with the Low Dew Point Dehumidifiers (LDP) that allows

for battery manufacturing in the most energy-efficient way. It comes with the capacity to

reduce energy consumption by 30% to 60%, which ultimately translates into an

overall reduction in the cost of the vehicle.

It can be said that desiccant dehumidification systems are at the core of successful EV transition. As failing to achieve the desired humidity levels during manufacturing can lead to the production of inferior-quality batteries, it increases the chances of an explosion, giving rise to safety concerns. Looking at the intensity of the situation, it is required that manufacturers install dehumidification technology to ensure the production of error-free, high-quality Li-ion batteries.

As Li-ion batteries play an instrumental role in powering the electric vehicles, the industry invariably seeks solutions to fast-track the battery manufacturing. Understanding this need, Bry-Air aces the manufacturing process by offering high performance energy efficient dehumidifiers in India and across the globe, for ensuring shortest manufacturing lead time of Li-ion batteries. It is the way forward for rendering a resilient infrastructure for Li-ion battery manufacturing in the future.

Authored article by Deepak Pahwa, Managing Director, Bry-Air

Post a Comment